Preservation and maintenance methods for tubular ultrafiltration membranes in winter

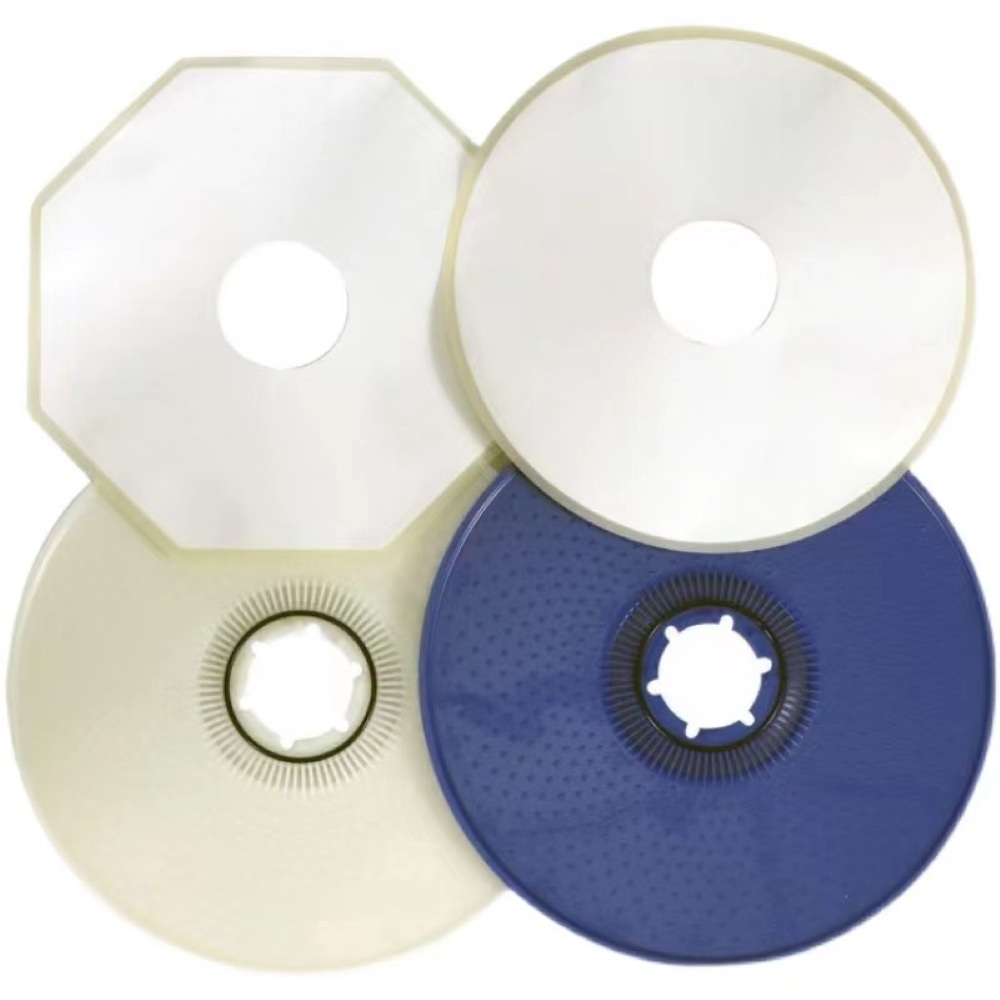

Preservation of film after installation

After the installation of membrane components on the ultrafiltration unit is completed, flushing must be carried out. The flushing work is usually carried out on the day or within two days of installation completion, and at the latest within four days. The following are the conditions required for flushing:

Complete the installation of ultrafiltration unit membrane components

The ultrafiltration unit was not rinsed with water (glycerol is still inside the membrane module)

Isolation ultrafiltration unit

To prevent mechanical damage and prevent membrane components from experiencing drastic temperature changes, especially rapid temperature drops. The operating temperature should not exceed 40oC (the membrane module should avoid direct sunlight). The price of membrane components slowly recovers to room temperature (usually 1 ℃/min). Failure to follow this procedure will seriously affect the quality of the membrane.

Long term preservation of membranes

The new tubular membrane components can be stored as spare parts in the warehouse. When storing, the components should be sealed to avoid excessive dryness and microbial contamination, and placed in a clean and dry environment at 1-35 ° C.

If the new membrane is stored for more than 6 months, 2 liters of protective solution should be injected into the membrane module. The protective solution is a mixture of water/glycerol/sodium bisulfite, with a ratio of 79:20:1 [weight%]

For membrane systems that have been shut down for a long time, tubular membrane components must prevent bacterial growth in order to extend the lifespan of the membrane.

Before long-term shutdown, the entire membrane system must be thoroughly cleaned, disinfected, and rinsed. If the membrane system stops running for more than a week, we recommend using a cleaning device to inject 1% sodium bisulfite solution into the membrane device for storage.

The membrane components used alone can be stored for a longer period of time after cleaning and disinfection, and then placed in the same water/glycerol/sodium bisulfite mixture as the new membrane protection.