Comprehensive Guide to MBR (Membrane Bioreactor) : Technology, Applications, and Benefits

Introduction: What is an MBR Membrane?

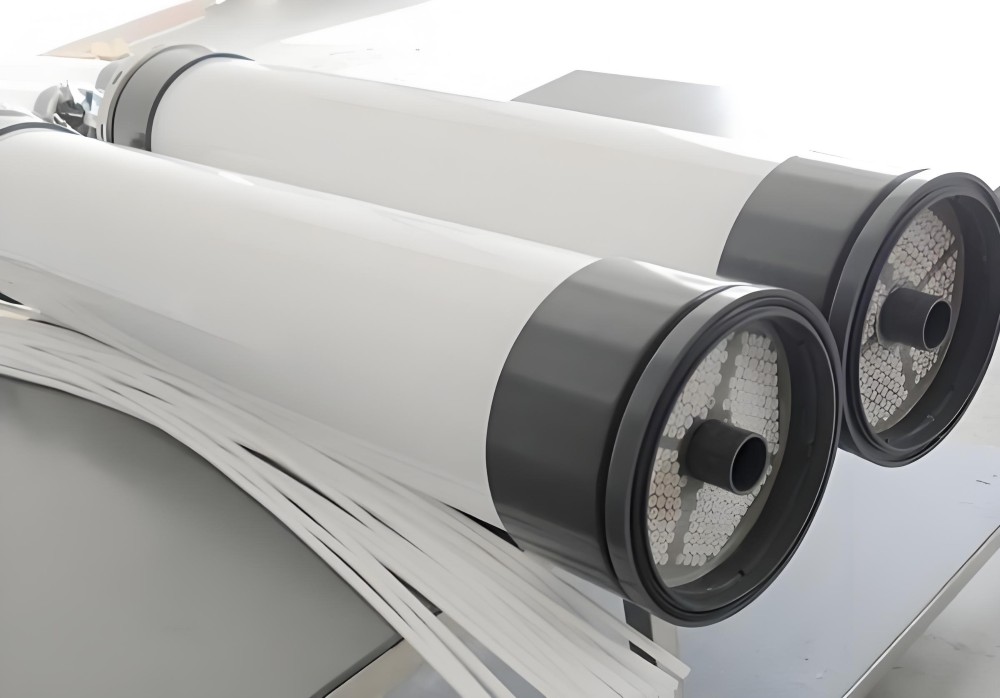

MBR (Membrane Bioreactor) membranes are a key component in advanced wastewater treatment technology. This combination of biological treatment (activated sludge) with membrane filtration offers an efficient, compact, and sustainable way to treat water. The technology is gaining widespread popularity for municipal, industrial, and decentralized wastewater treatment applications, especially where high-efficiency, compact designs, and water reuse are necessary.

What is a Membrane Bioreactor (MBR) System?

A Membrane Bioreactor (MBR) system integrates two primary processes: biological treatment and membrane filtration. In an MBR, wastewater undergoes biological treatment to break down organic matter, followed by membrane filtration to separate the treated water from suspended solids, bacteria, and other pollutants. The result is cleaner water that is of higher quality compared to traditional treatment methods, making it suitable for discharge or reuse.

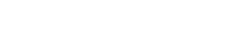

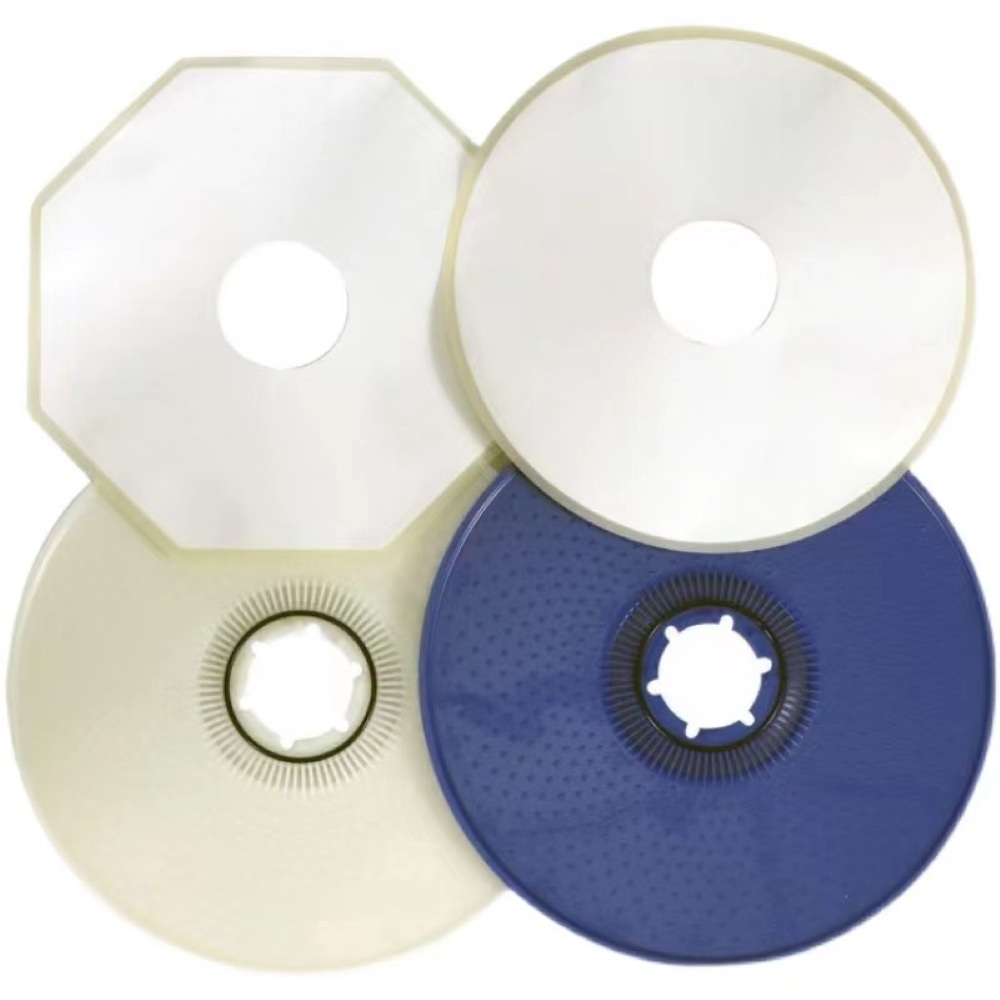

MBR membranes are typically made from synthetic polymers such as Polyvinylidene Fluoride (PVDF), Polysulfone (PS), or ceramics, designed to allow only filtered water and smaller dissolved substances to pass through, while retaining larger particles, pathogens, and organic matter.

Key Functions of MBR Membranes

1. Efficient Filtration:

MBR membranes are designed for superior filtration, removing suspended solids, bacteria, and pathogens from wastewater. The semi-permeable nature of the membrane ensures that only clean water passes through, leaving behind pollutants.

2. Enhanced Biological Treatment:

By integrating biological treatment with membrane filtration, MBR systems provide higher biodegradation rates, improving the overall treatment process. This allows for effective removal of organic compounds and nutrients, such as nitrogen and phosphorus.

3. Reduced Footprint:

One of the primary advantages of MBR membranes is the compact nature of the system. Unlike conventional wastewater treatment plants that require large sedimentation tanks, MBR systems can be much smaller, saving space while maintaining high treatment efficiency.

4. Consistent Effluent Quality:

The membranes in MBR systems produce high-quality effluent with low suspended solids and pathogens, making the water safe for reuse or discharge into natural water bodies.

Applications of MBR Membranes

1. Municipal Wastewater Treatment:

MBR technology is widely used in urban and suburban wastewater treatment plants. It is especially valuable in regions where space is limited and where high-quality effluent is needed for discharge or reuse. MBR systems can handle varying wastewater loads, providing consistent results even under fluctuating conditions.

2. Industrial Effluent Treatment:

Industries such as pharmaceuticals, food and beverage processing, textiles, and petrochemical facilities produce wastewater that is often rich in organic matter and chemicals. MBR systems are ideal for treating complex industrial effluents, providing reliable treatment and ensuring compliance with environmental discharge standards.

3. Water Reuse and Recycling:

MBR membranes enable water reuse for non-potable applications such as irrigation, industrial cooling, and even toilet flushing. The treated effluent meets high standards, making it safe for these applications and contributing to water conservation efforts.

4. Decentralized Wastewater Treatment:

In remote or off-grid locations, where connecting to a centralized sewer system is not feasible, MBR technology offers a cost-effective and space-efficient solution for wastewater treatment. It is ideal for small communities, resorts, and industries in isolated regions.

5. Desalination and Brine Treatment:

MBR membranes are also used in desalination plants to remove contaminants from seawater, providing clean water in areas facing water scarcity. The technology also plays a key role in treating brine, a byproduct of desalination, which can be difficult to manage.

6. Tertiary Treatment for Advanced Filtration:

In existing wastewater treatment plants, MBR membranes are used as a tertiary treatment step, polishing the effluent after primary and secondary treatment. This provides an additional layer of filtration, ensuring that the treated water is of the highest quality possible.

Advantages of MBR Membranes

1. Higher Effluent Quality:

MBR systems produce treated water of higher quality than conventional methods. The water is virtually free from suspended solids, organic matter, and pathogens, making it suitable for discharge or reuse.

2. Compact and Space-Efficient:

MBR systems save valuable space compared to traditional treatment technologies, which require large settling tanks. Their compact nature makes them ideal for urban areas or locations with limited space.

3. Reduced Sludge Production:

The MBR process generates less sludge than conventional activated sludge systems. This reduces the need for sludge disposal, making the system more environmentally friendly and cost-effective in the long term.

4. Low Operating Costs:

MBR systems are generally energy-efficient and have lower operating costs compared to other advanced treatment technologies. Their automated operation reduces the need for manual labor and ensures consistent performance.

5. Scalability and Flexibility:

MBR technology can be easily scaled to meet the needs of small, medium, or large treatment facilities. Whether treating municipal wastewater or industrial effluents, MBR systems can be designed and sized to accommodate various flow rates and treatment requirements.

Challenges and Considerations

1. Membrane Fouling:

One of the challenges of MBR systems is membrane fouling, where particles and microorganisms accumulate on the membrane surface, reducing filtration efficiency. Regular maintenance, cleaning, and pre-treatment processes can mitigate fouling and prolong the lifespan of the membranes.

2. High Initial Costs:

The initial installation cost of MBR systems can be higher compared to traditional wastewater treatment technologies. However, this can be offset over time through lower operational costs, reduced energy consumption, and water reuse.

3. Maintenance Requirements:

While MBR systems are low-maintenance compared to some other treatment methods, they still require regular monitoring and cleaning of the membranes to ensure optimal performance.

Conclusion: The Future of Wastewater Treatment with MBR Membranes

MBR membranes are at the forefront of wastewater treatment technology, offering high-quality effluent, compact systems, and sustainability. As water scarcity becomes an increasingly important global issue, the role of MBR systems in water reuse and efficient wastewater management will continue to grow. Their ability to treat complex industrial effluents, reduce environmental impact, and produce water that is safe for reuse makes MBR technology an essential tool for future water management practices.