Ultimate Guide to Ultrafiltration (UF) Membranes: Revolutionizing Water Purification and Industrial Processes

In today's world, where access to clean water is paramount amid growing environmental concerns and industrial demands, ultrafiltration (UF) membranes have become a cornerstone of efficient filtration solutions. These advanced systems offer a reliable method for separating contaminants from liquids, ensuring high-quality outputs with minimal environmental impact. This detailed guide explores the essentials of UF membranes, from their core principles to practical implementations, benefits, and evolving trends. Ideal for engineers, researchers, and decision-makers in water management, this article highlights how UF technology is driving sustainability in diverse sectors. Whether you're optimizing wastewater recycling or enhancing product purity in manufacturing, understanding UF membranes can unlock significant operational advantages.

Defining Ultrafiltration Membranes

Ultrafiltration membranes are semi-permeable barriers designed to filter out particles based on size, typically ranging from 0.001 to 0.1 micrometers in pore diameter. This places UF between microfiltration (larger pores) and nanofiltration or reverse osmosis (smaller pores), making it ideal for removing suspended solids, macromolecules, and microorganisms without eliminating dissolved salts.

Constructed from durable materials like polysulfone (PS), polyacrylonitrile (PAN), or ceramic compounds, UF membranes are engineered for resilience against chemical exposure and mechanical stress. Their selectivity stems from a porous structure that allows water and small solutes to pass while retaining larger entities such as viruses, proteins, and colloids. Unlike chemical treatments, UF relies on physical separation, promoting eco-friendly processes with reduced chemical usage.

Key characteristics include molecular weight cut-off (MWCO), which indicates the size of molecules rejected (often 1,000 to 500,000 Daltons), and flux rate, measuring permeation efficiency. These attributes make UF membranes versatile for both potable water production and industrial fluid clarification.

The Mechanics Behind UF Membrane Operation

UF systems operate via pressure-driven filtration, where feed liquid is forced through the membrane at pressures of 1-10 bar. The process can be described in phases:

Feed Introduction: Raw liquid enters the system, encountering the membrane surface.

Selective Permeation: Smaller components permeate as "filtrate," while larger ones form a concentrate or retentate.

Concentration Polarization Management: To prevent buildup on the membrane, cross-flow or dead-end modes are used; cross-flow recirculates retentate to minimize fouling.

Cleaning Cycles: Periodic backflushing or chemical washes restore performance by removing accumulated debris.

Configurations vary: dead-end for low-solid feeds and cross-flow for high-viscosity applications. Advanced setups incorporate turbulence promoters or vibratory mechanisms to enhance flux and extend membrane life. Energy efficiency is a focus, with modern designs achieving recoveries up to 95% in optimized loops.

Compelling Advantages of UF Membranes

Adopting UF technology yields multiple benefits, setting it apart in filtration landscapes:

Exceptional Contaminant Removal: UF excels at eliminating turbidity, pathogens, and organics, often achieving >99% rejection of bacteria and viruses, surpassing conventional sand filters.

Operational Efficiency: With lower pressure requirements than RO, UF consumes less energy (typically 0.1-0.5 kWh/m³), reducing costs and carbon footprints.

Modular and Scalable Design: Systems are compact, fitting into existing infrastructures, and scalable from lab-scale to mega-plants handling millions of liters daily.

Chemical-Free Operation: Minimal reliance on coagulants or disinfectants preserves water's natural composition and avoids byproduct formation.

Longevity and Reliability: High-quality membranes last 5-15 years with proper care, offering predictable performance in variable conditions.

Drawbacks like membrane fouling are mitigated through innovations in hydrophilic coatings, balancing overall value.

Varieties of UF Membranes

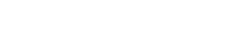

UF membranes are categorized by geometry and material to match specific needs:

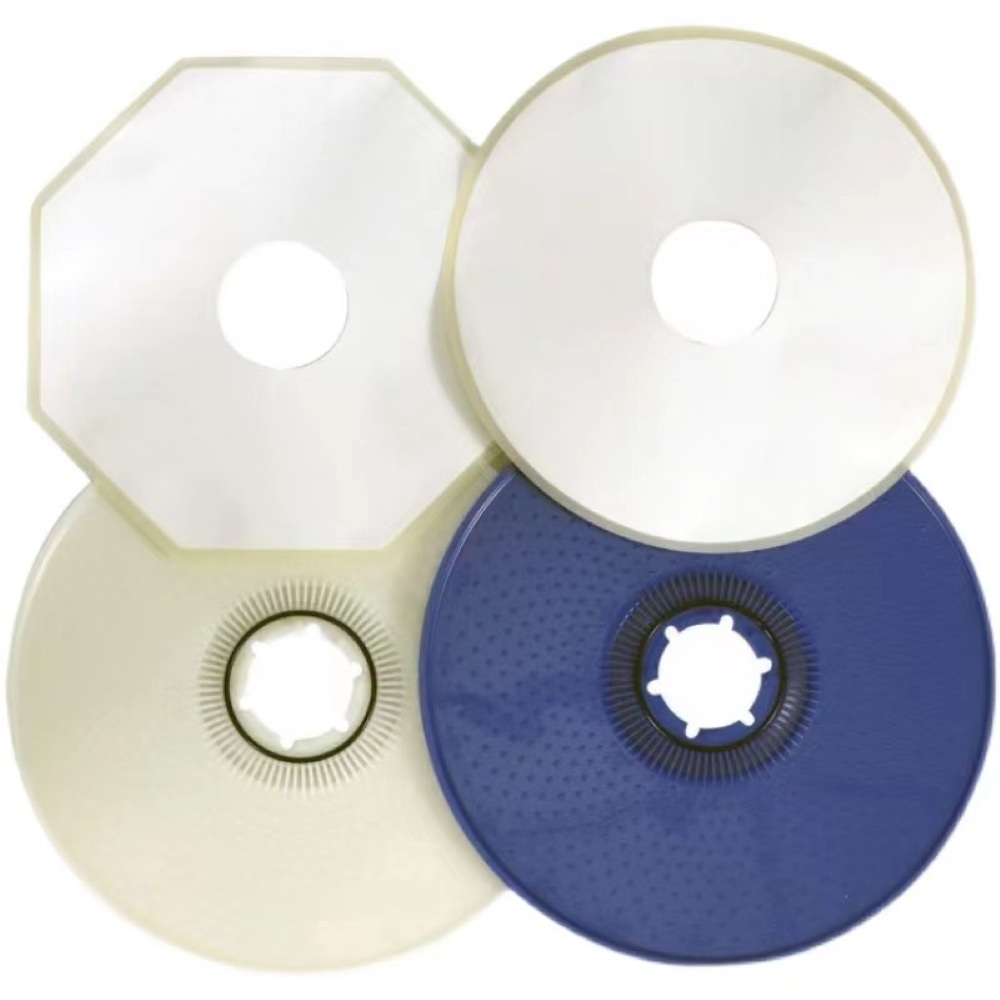

Hollow Fiber Membranes: Bundles of thin tubes provide high surface area, suited for large-volume water treatment due to ease of cleaning via backwashing.

Spiral-Wound Membranes: Layered sheets wound around a core, compact for industrial reuse applications but prone to clogging in high-solid streams.

Tubular Membranes: Larger diameter tubes handle viscous or abrasive feeds, common in food processing for their robustness.

Material options include organic polymers for cost-effectiveness and inorganics like alumina ceramics for extreme pH or temperature resistance. Hybrid composites, blending polymers with nanoparticles, enhance antifouling properties and selectivity.

Broad Spectrum of UF Membrane Applications

UF membranes serve myriad industries, adapting to unique challenges:

Drinking Water Production: In municipal plants, UF purifies surface water by removing cryptosporidium and giardia, supporting safe supply in regions like Europe and Asia.

Wastewater Reclamation: Tertiary treatment in sewage facilities recycles effluent for irrigation or industrial cooling, aiding water-scarce areas.

Food and Beverage Sector: Clarifies juices, concentrates dairy products, and sterilizes beer, maintaining flavors while ensuring hygiene.

Pharmaceutical and Biotech: Isolates biomolecules, purifies vaccines, and desalinates process streams, meeting stringent purity standards.

Oil and Gas: Treats produced water, separating emulsions for reinjection or discharge compliance.

Innovative uses extend to aquaculture for recirculating systems and mining for tailings dewatering, showcasing UF's adaptability.

Guidelines for Installation and Upkeep

Successful UF deployment requires strategic planning:

System Design: Assess feed quality, desired output, and flow rates; integrate pre-filters to protect membranes.

Setup Process: Assemble modules in housings, connect pumps and controls, and commission with pilot tests to calibrate pressures.

Routine Maintenance: Monitor transmembrane pressure rises indicating fouling; employ clean-in-place (CIP) protocols using mild acids or bases quarterly.

Performance Optimization: Use sensors for real-time data, replacing elements when flux drops below 70% of initial levels.

Expert consultation from suppliers ensures compliance with regulations like NSF/ANSI standards.

Emerging Trends in UF Membrane Technology

The UF market, valued at over $2 billion in 2024, is evolving rapidly:

Sustainable Materials: Biodegradable polymers and recycled composites reduce environmental impact.

Smart Integration: IoT-enabled monitoring predicts fouling, while machine learning optimizes cleaning schedules.

Hybrid Systems: Combining UF with forward osmosis or electrodialysis enhances efficiency for zero-liquid discharge goals.

Nanotech Enhancements: Graphene-infused membranes boost flux by 50% and resist biofouling.

By 2035, projections indicate widespread adoption in developing economies, driven by urbanization and climate resilience needs.