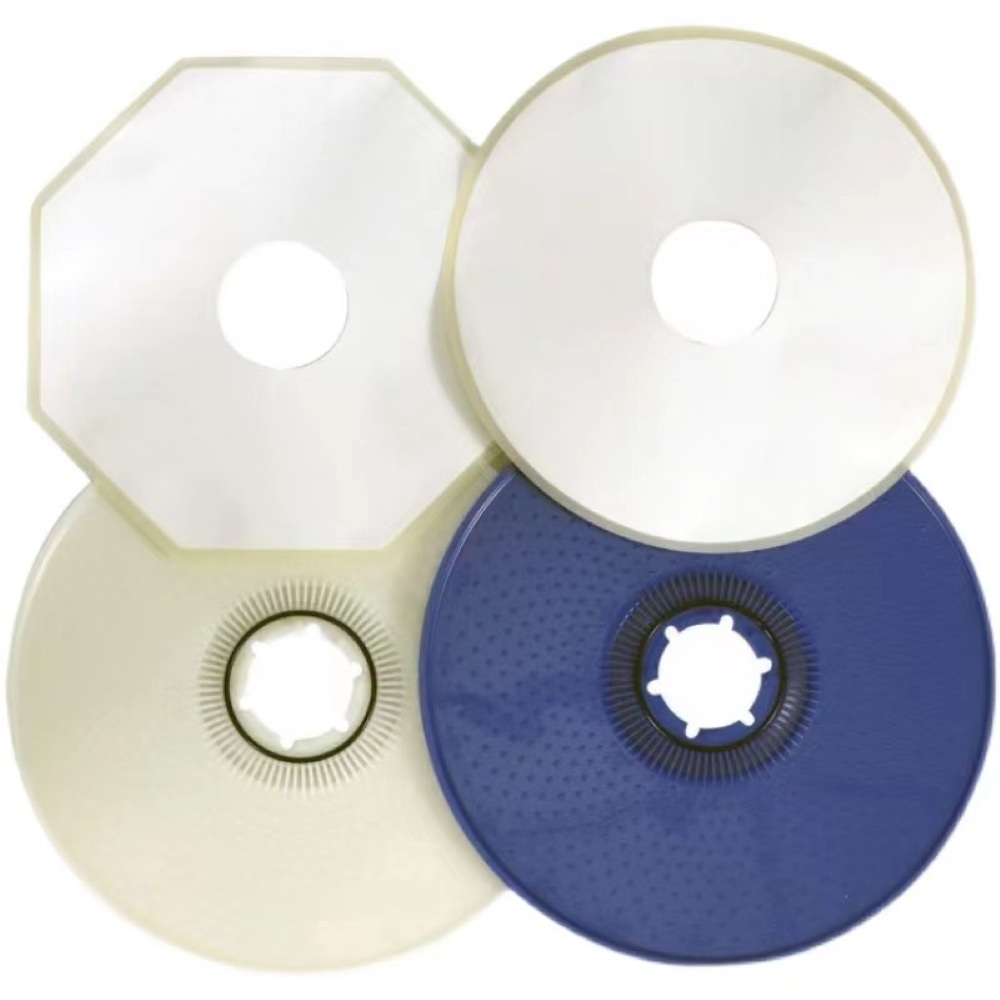

With increasingly strict environmental emission standards, stable, reliable, and efficient environmental protection equipment is also increasingly favored by polluting units. Among them, external MBR membrane equipment has become an indispensable part of high concentration organic wastewater such as leachate, and tubular membranes often encounter membrane tube blockage problems in application.

There are two types of blockages:

1. Membrane tube wall blockage (i.e. filter aperture blockage) is mainly manifested as: no significant changes in circulating flow rate and membrane inlet pressure, and low water production flow rate; The main reasons for this blockage are as follows:

① Incomplete biochemistry, poor sludge properties, and high viscosity; Solution: The main way to improve the sludge properties is to check the water quality and design indicators of the front-end process.

② The water contains pollutants such as PAM and silicon-based defoamers. Kitchen oils and fats are factors that affect the flux of contaminated membranes.

For membrane wall fouling, suitable cleaning agents can be found through pollutant dissolution experiments and solved through online chemical cleaning to restore flux.

2. Membrane tube blockage (i.e. filter channel blockage) is mainly manifested as a decrease in circulating flow rate, an increase in membrane inlet pressure, and a decrease in water production flow rate; The main reasons for this blockage are as follows:

① When adding activated sludge for biochemical cultivation, there was no mud washing and screening, resulting in a large amount of fibers being present in the biochemical system. The system entered the membrane tube during operation, causing blockage. In the early stage of ultrafiltration operation, it should be filtered through a filter before entering the membrane system. The filter should be cleaned for more than one day before entering the membrane system;

② Basket filters should choose 800um perforated mesh and promptly clean the trapped fibers;

③ After the ultrafiltration is shut down, it should be flushed in a timely manner (by opening the production water valve, cleaning the inlet valve, and returning the reflux valve to the biochemical tank). The concentrated water should be completely flushed back to the biochemical tank without passing through the circulation pump;

④ In case of power outage or emergency stop of the system, manually drain the sludge inside the membrane tube in a timely manner to avoid compaction;

⑤ Protect the inlet flow rate, circulation flow rate, and pressure settings to avoid dead end filtration.

There are several methods for dealing with membrane blockage:

Use a cleaning pump for low-pressure and high flow flushing. If the blockage is not tight, this method can generally be used to flush it out.

II. Use a hose to poke the membrane. An 8mm membrane tube can be inserted into the blocked membrane tube using a 6mm nylon hose (the nylon tube end needs to be smoothed)

In cases where the effectiveness of the above two methods is not significant, our company's developed membrane dredging tool can be used for efficient dredging. The usage method is as follows:

1. The blocking body is in a soft rubber state. Connect the membrane washer to a water pump and use water pressure to flush the membrane holes of the membrane tube.

2. The blockage is in the form of hard particles. Connect the membrane washer to a water pump and use water pressure to flush the membrane holes of the membrane tube. Press and rotate the outer handle of the membrane washer to break the blockage and flush out the tube body.

Attention: After the membrane tube program is flushed, the system should be washed with medication and water, and then turned on for use.

If you have any issues with the applicability of tubular ultrafiltration membranes, please contact our company and we will work together to ensure the stable operation of your system.