In landfills, after several days or even years of garbage decomposition, accompanied by precipitation, surface water, and groundwater infiltration, brown black garbage leachate is produced, commonly known as "garbage soup".

The 2008 version of the standard for leachate from garbage can be called the "strictest in the world". Not only is it stricter than similar standards in most developed countries, but it is also stricter than other industries such as chemical and pharmaceutical industries in China. From first tier cities to small county towns, landfill sites and even regulatory authorities are tackling the challenge of how to meet emission standards under very strict national standards?

The environmental protection water circle has selected 24 cases of garbage leachate treatment projects for everyone. The detailed explanation is as follows:

Anhui Province Garbage Leachate Treatment Project

Case 1

Project Name: Guangzhou Huahao Energy and Environmental Protection Group Co., Ltd

Project Name: Expansion Project of Leachate Treatment for a Domestic Waste Incineration Power Generation Project in Hefei City

Project scale: 400 t/d

Running time: 2016

Processing technology: pretreatment system (pre settling tank+regulating tank)+anaerobic system (UASB)+MBR system (two-stage A/O+UF)+NF

Emission standard: The maximum allowable emission concentration of leachate treatment pollution in this project should be in accordance with the current national standard "Comprehensive Emission Standard for Leachate" (GB8978-1996) Level 1 standard, and some indicators should comply with the standards of the leachate plant in Hefei Demonstration Park

Project features: Reasonable process design, excellent construction quality, stable and compliant operation, making it a representative project of domestic waste incineration power plants

Case 2

Project Name: Wuhan Weimeng Environmental Protection Technology Co., Ltd

Project Name: Leachate Treatment Project of a Domestic Waste Landfill in a County, Anhui Province

Project scale: 120 t/d

Running time: 2016

Processing technology: pretreatment system+A/O+two-stage electrochemistry+A/O

Emission Standard: Pollution Control Standard for Landfills of Domestic Waste GB16889-2008 (Table 2)

Project features: Unlike traditional membrane processes for treating leachate, this process adopts a non membrane process of biochemistry and electrochemistry, without the production of concentrated solution!

Case Three

Project Name: Wuhan Tianyuan Environmental Protection Co., Ltd

Project Name: Bengbu Landfill Leachate Treatment Project

Project scale: 300 t/d

Operation time: Leachate in October 2011, concentrated solution in October 2015

Processing technology:

Leachate adopts "pretreatment+MBR (two-stage)+NF/RO"

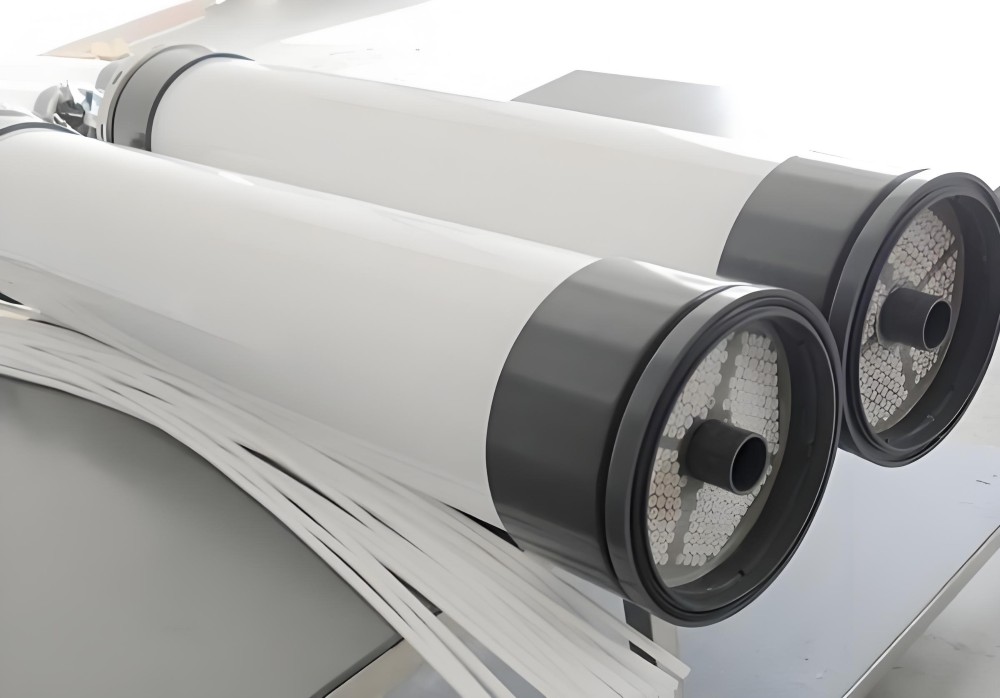

The concentrated solution adopts "MVR (tube evaporator)"

Emission standards: Table 2 of the "Pollution Control Standards for Landfills of Municipal Solid Waste" (GB16889-2008)

Project features: Excellent representative in concentrated liquid treatment engineering

Hubei Province Garbage Leachate Treatment Project

Case Four

Project Name: Nanjing Wandesi Environmental Protection Technology Co., Ltd

Project Name: Yichang Xiaoting Domestic Waste Sanitary Landfill Construction Project - Leachate Treatment Station Construction Project Case

Project scale: 300 t/d leachate+100 t/d concentrate

Running time: 2016

Processing technology:

Leachate: pretreatment+A/O+MBR+NF+RO

Concentrated leachate: pretreatment+MVR evaporation process

Emission standard: The discharge water quality meets the standards in Table 2 of the "Pollution Control Standards for Landfills of Municipal Solid Waste" (GB16889-2008).

Project features: The concentrated leachate adopts the "pretreatment+MVR" process, which has mature equipment and technology, small footprint, and the ability to precipitate and recover salts. It effectively solves the problem of concentrated liquid treatment and greatly reduces secondary pollution.

Garbage leachate has the characteristics of high concentration of organic pollutants, complex composition, high concentration of ammonia nitrogen, high salt content, poor biodegradability, strong toxicity, and high content of heavy metal ions. Currently, the most commonly used process in engineering is the "pretreatment+AO-MBR+NF+RO" process, which runs stably and has good treatment effect. The final effluent can meet the standards of Table 2 or Table 3 of the "Pollution Control Standard for Landfill Sites of Domestic Waste GB16889-2008".

Beijing Municipal Solid Waste Leachate Treatment Project

Case Five

Project Name: Beijing Jielv Technology Development Co., Ltd

Project Name: Beijing Shougang Biomass Energy Waste Leachate Treatment Project

Project scale: 900 t/d

Running time: 2013

Processing technology: medium temperature anaerobic+membrane bioreactor (MBR)+nanofiltration (NF)+reverse osmosis (RO)

Emission standard: The maximum allowable emission concentration of leachate treatment pollution in this project should be in accordance with the current national standard "Comprehensive Emission Standard for Leachate" (GB8978-1996) Level 1 standard, and some indicators should comply with the standards of the leachate plant in Hefei Demonstration Park

Project characteristics: This project has the strictest treatment standards in China (CODcr<30mg/L). In 2013, it was declared as a Beijing Science and Technology Plan project and was rated as the "Development and Demonstration Project of Low Energy Consumption Treatment Technology for Leachate from Garbage Incineration Power Plants"

Shaanxi Province Garbage Leachate Treatment Project

Case Six

Project Name: Jiangsu Yunshuiyao Environmental Technology Co., Ltd

Project Name: Datong Municipal Solid Waste Incineration Plant Leachate Treatment Project

Project scale: 200 t/d

Processing technology: UASB+MVC evaporation+DI ion exchange

Emission standards: Table 2 standard of "Pollution Control Standards for Landfills of Domestic Waste" (GB16889-2008).

Project features: The recovery rate can reach up to 90%, and a small amount of concentrated liquid can be re sprayed for treatment, making it possible to achieve zero discharge treatment of leachate from incineration plants.

Shandong Province Garbage Leachate Treatment Project

Case Seven

Project Name: Beijing Tiandiren Environmental Protection Technology Co., Ltd

Project Name: Qingdao Xiaojianxi Garbage Comprehensive Treatment Plant Leachate Treatment Expansion and Renovation Project

Project scale: 900 t/d

Running time: 2011

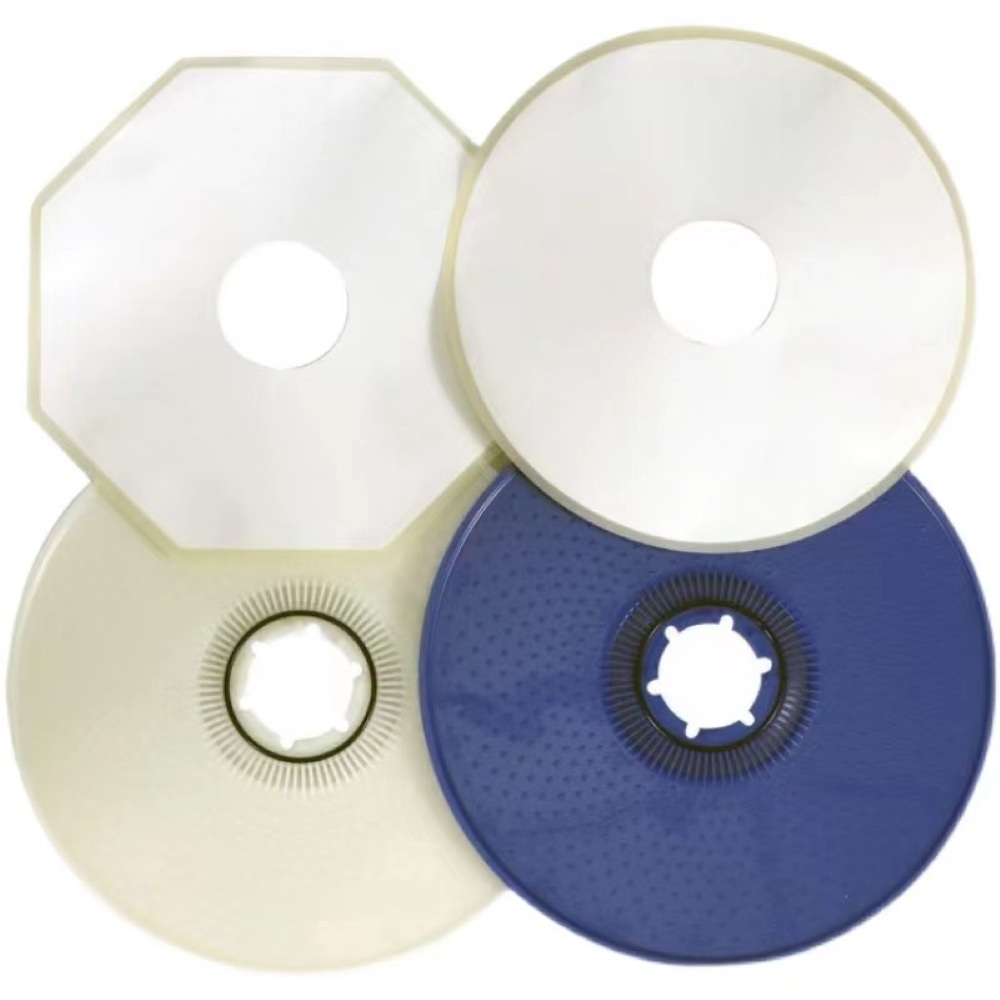

Processing technology: "Membrane Bioreactor (MBR)+Disc Tube Reverse Osmosis (DTRO)+Aerated Zeolite Biofilter"

Emission standard: Class A of the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002)

Project features: The water source comes from mixed water from incineration plants, landfills, and composting plants; High effluent discharge standards; Won the 2012 Ministry of Housing and Urban Rural Development Technology Demonstration Project

Case Eight

Project Name: Jiangsu Jinshan Environmental Protection Company

Project Name: Leachate Treatment Project of Heze Municipal Solid Waste Comprehensive Treatment Plant in Shandong Province

Project scale: 150 t/d

Processing technology: A/O+UF+NF+RO process

Emission standard: "Pollution Control Standards for Landfills of Domestic Waste" (GB16889-2008)

Project feature: Through water balance, no concentrated liquid needs to be processed

Shanxi Province Garbage Leachate Treatment Project

Case Nine

Project Name: Xinjiang Hengyi Environmental Protection Technology Co., Ltd

Project Name: Shanxi Solid Waste Disposal Center Urban Domestic Waste Leachate Treatment Project

Project scale: 100 t/d

Running time: 2011

Processing technology: pretreatment system (regulating tank+coagulation sedimentation)+anaerobic system (UASB)+SBR+MBR+RO system

Emission standard: Emission standard of "Pollution Control Standards for Landfills of Municipal Solid Waste" (GB16889-2008)

Project features: The combination of low energy consumption and high load UASB and SBR treatment process is an effective way to remove organic matter and ammonia nitrogen from leachate, and is the main treatment process of the system.

Sichuan Province Garbage Leachate Treatment Project

Case 10

Project Name: China Municipal Engineering North China Design and Research Institute

Project Name: Chengdu Solid Waste Sanitary Disposal Site Leachate Treatment Expansion Project

Project scale: 1000 t/d

Processing technology: MBR+NF+RO process is adopted, and the concentrated solution adopts coagulation precipitation+UF+AOP+BAC process

Emission standards: Table 2 of the Pollution Control Standards for Landfills of Municipal Solid Waste (GB16889-2008)

Project features: In addition to meeting the standard for leachate discharge, concentrated solution can also meet the standard for discharge

Case Eleven

Project Name: Chengdu Xingrong Group

Project Name: Chengdu Wanxing Power Plant Garbage Leachate Treatment Project

Project scale: 850 t/d

Processing technology: Adopting the "MBR+NF+RO/DTRO" process

Guangdong Province Garbage Leachate Treatment Project

Case 12

Project Name: Beijing Jielv Technology Development Company

Project Name: Zhuhai Xikengwei Landfill Leachate Treatment Phase II Project

Project scale: 660 t/d

Processing technology: "Anaerobic+Membrane Bioreactor (MBR)+Nanofiltration (NF)/Reverse Osmosis (RO)"

Emission standards: Table 2 of the Pollution Control Standards for Landfills of Municipal Solid Waste (GB16889-2008) and the effluent water quality requirements of the Guangdong Province's Water Pollution Discharge Limitation Standards (DB44/26-2001)

Project feature: Low operating costs in the same process

Case 13

Project Name: Zhuhai Water Group

Project Name: Guangdong Zhuhai Xikengwei Garbage Sanitary Landfill Leachate Treatment Station Phase II Project

Project scale: 660 t/d

Processing technology: Adopting "medium temperature anaerobic+membrane bioreactor MBR+membrane deep treatment NF/RO"

Emission standards: The wastewater discharge from the leachate treatment station complies with the stricter requirements of Table 2 of the "Pollution Control Standards for Landfills" (GB 16889-2008) and the first level standard of the second period of the "Water Pollutant Discharge Limits" (DB44/26-2001) in Guangdong Province

Jiangsu Province Garbage Leachate Treatment Project

Case 14

Project Name: Beijing Tiandiren Environmental Protection Technology Co., Ltd

Project Name: Nantong Municipal Waste Treatment Center Landfill Leachate Upgrading and Renovation Project in Jiangsu Province

Project scale: 200 t/d

Running time: 2013

Processing technology: MBR+DTRO+post-treatment+concentrated solution treatment

Emission standards: Table 3 of the "Pollution Control Standards for Landfills of Municipal Solid Waste" (GB16889-2008)

Project features: The process includes a DTZ concentrated liquid treatment system, which solves the problem of concentrated liquid.

Case 15

Project Name: Jiangsu Weili Environmental Protection Technology Co., Ltd

Project Name: Nanjing Shuige Organic Waste Treatment Plant Sewage Treatment Station Renovation and Expansion Project

Project scale: 800 t/d

Running time: 2013

Processing technology: MBR (two-stage)+NF/RO

Emission standards: Table 2 of the Pollution Control Standards for Landfills of Municipal Solid Waste (GB16889-2008)

Project features: Enhanced denitrification process, non full scale RO, generally NF effluent meets the standard, which can reduce the production of concentrated solution.

Jilin Province Garbage Leachate Treatment Project

Case 16

Project Name: Dalian Guangtaiyuan Environmental Protection Technology Co., Ltd

Project Name: Emergency Project for Leachate from Mogugou Municipal Solid Waste Sanitary Landfill in Changchun City

Project scale: 600 t/d

Running time: 2013

Processing technology: MVR evaporation

Emission standards: Table 3 of the "Pollution Control Standards for Landfills of Municipal Solid Waste" (GB16889-2008)

Project features: No biochemical process, not affected by low temperatures in northern winter.

Tianjin Municipal Solid Waste Leachate Treatment Project

Case 17

Project Name: Wuxi Hedan Environmental Protection Company

Project Name: Tianjin Binhai New Area Dagang Garbage Incineration Power Plant Leachate Treatment Project

Project scale: 300 t/d

Running time: 2013

Processing technology: CLR (anaerobic system)+HDR (high-efficiency aerobic system)+A3O3 (three-stage AO system)

Emission standard: Grade III standard of Comprehensive Wastewater Discharge Standard (DB12/356-2008)

Project features: This process belongs to the non membrane process, which can avoid membrane replacement and concentrated liquid production

Shanghai Municipal Solid Waste Leachate Treatment Project

Case 18

Project Name: Jiangsu Weili Environmental Protection Technology Co., Ltd., Sumitomo Precision Industrial Technology (Shanghai) Co., Ltd

Project Name: Shanghai Laogang Landfill Leachate Treatment Project

Project scale: 1600 t/d incineration plant leachate+1600 t/d landfill leachate

Processing technology: MBR+NF+RO/MVC process is adopted, and the concentrated solution adopts advanced ozone oxidation combination technology (SHAS) technology

Project features: Large scale, thorough treatment of concentrated solution

Zhejiang Province Garbage Leachate Treatment Project

Case 19

Project Name: Hangzhou Environment Group Co., Ltd., Qinghai Jieshen Environmental Energy Industry Co., Ltd., South China University of Technology

Project Name: Hangzhou Tianziling Landfill Leachate Treatment Project

Project scale: 1200 t/d

Processing technology: JSBC+secondary Fenton+secondary BAF

Project feature: No membrane process is used, therefore no concentrated solution is produced

Case 20

Project Name Enterprise: Zhejiang Tailai Environmental Protection

Project Name: Xiangshan Landfill Leachate Treatment Project

Project scale: 400 t/d

Processing technology: Adopting "MBR+NF+RO/AOP"

Case 21

Project Name: Shanghai Kangheng Environment Co., Ltd

Project Name: Treatment of Leachate from Garbage Incineration Plant in Yinzhou District, Ningbo City

Project scale: 800 t/d

Processing technology: "MBR+NF+RO"

Heilongjiang Province Garbage Leachate Treatment Project

Case 22

Project Name: Sande Group, Nanjing Ruijiete Membrane Separation Technology Co., Ltd

Project Name: Heilongjiang Province Urban Domestic Waste Leachate Treatment Project

Project scale: 100 t/d

Processing technology: pre-treatment system (regulating tank+coagulation sedimentation)+anaerobic system (UASB)+two-stage A/O+MBR+RO system

Emission standard: Emission standard of "Pollution Control Standards for Landfills of Municipal Solid Waste" (GB16889-2008)

Project features: Two stage A/O enhanced denitrification, efficient MBR flat membrane stable and compliant discharge

Guangxi Province Garbage Leachate Treatment Project

Case 23

Project Name: Guangxi Huadu Environmental Investment Co., Ltd., Guangxi Jinyuan Environmental Protection Technology Co., Ltd

Project Name: Leachate Treatment Project of Shanglin County Domestic Waste Sanitary Landfill

Project scale: 100 t/d

Processing technology: pretreatment (coagulation+magnetic flocculation)+"anaerobic+aerobic+MBR+ultrafiltration+reverse osmosis"

Emission standard: After the effluent water quality meets the first level standard of the "Environmental Pollution Standard for Sanitary Landfills of Domestic Waste" (GB16889-2008), it will be discharged

Project features: Ultra magnetic coagulation technology is used for pre-treatment of leachate. The leachate from garbage is treated by magnetic coagulation from the inlet to the outlet in only about 15 minutes.

Shenzhen Municipal Solid Waste Leachate Treatment Project

Case 24

Project Name: Shanghai Jingyu Environmental Engineering Co., Ltd

Project Name: Shenzhen Laohukeng Leachate Treatment Station Phase II Zero Emission Treatment Project

Project scale: 1745 t/d

Processing technology: TSMM garbage leachate concentrate specialized equipment, biochemical, anaerobic MBR、 Concentrated solution nanofiltration, reverse osmosis

Discharge standard: The effluent meets the water quality standard for use as make-up water for open circulating cooling water in the "Industrial Water Quality for Urban Wastewater Reuse" (GB/T 19923-2005).

Project features: Total effluent volume: 1736m3/d; Total recovery rate: 99.5%, used for cooling circulating water in the factory area; Organic concentration: 0.5%, resource utilization; Produce a concentrated solution with high salt content: 20%, which is then evaporated and crystallized to produce salt products.