Are you need Membrane solutions? Free For Business

Introduction to ultrafiltration membrane technology

Ultrafiltration technology uses selective porous membranes as separation media, allowing the separated solution to pass through the membrane with a certain driving force (such as pressure difference, concentration difference, potential difference, etc.), allowing low molecular solutes to pass through the membrane and large molecular solutes to be intercepted, in order to separate substances of different molecular weights in the solution and achieve the goals of separation, concentration, and purification.

Ultrafiltration can almost completely intercept suspended solids, colloids, microorganisms, large organic molecules, and bacteria in water, while inorganic salts and small organic molecules can pass through. People are increasingly recognizing the wide range of applications of ultrafiltration membrane separation technology in various water treatment and liquid separation fields.

Introduction to membrane material

Common membrane materials include polyvinylidene fluoride (PVDF), polypropylene nitrile (PAN), polyethersulfone (PES), polysulfone (PS), cellulose acetate (CA), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc. In earlier years, the water treatment market was dominated by polysulfone, cellulose acetate, and polypropylene membranes. But now, polyvinylidene fluoride and polyether sulfone have become the most widely used ultrafiltration and microfiltration membrane materials. Among them, polyvinylidene fluoride (PVDF) material is increasingly favored by people due to its unparalleled superior characteristics.

Advantages of Polyvinylidene Fluoride (PVDF) Membrane Material

In order to ensure the excellent performance of the membrane, it is necessary to control the surface characteristics and supporting structure of the membrane during the production process of ultrafiltration and microfiltration membranes. At the same time, the membrane material must also have good mechanical properties to ensure that the produced membrane has high strength and flexibility. Moreover, the membrane material should also have excellent chemical resistance.

The biggest characteristic of polyvinylidene fluoride is its extremely high chemical stability. And chemical stability determines its outstanding antioxidant capacity and acid alkali resistance. The most common and headache inducing problem encountered during the application of membranes is membrane fouling and blockage. During the water treatment process, microorganisms and organic matter in the water (especially in wastewater) often adhere to the surface of the membrane. As the membrane is used for a longer period of time, these substances will gradually block the membrane pores. This resulted in a direct decrease in membrane separation capability. To ensure the normal operation of the membrane and stable water flux, it is necessary to regularly clean the membrane. The most effective method to remove these microorganisms and organic matter adsorbed on the membrane surface is through oxidant cleaning. But oxidants can cause damage to many membranes. The ability of polyvinylidene fluoride (PVDF) to withstand oxidants (such as sodium hypochlorite) is more than 10 times that of materials such as polyethersulfone and polysulfone, greatly extending its service life.

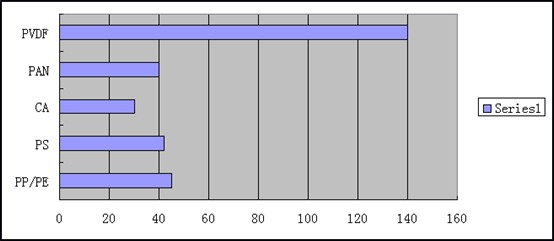

Comparison of toughness of various membrane materials

Although both polysulfone and polyvinylidene fluoride have high strength, polyvinylidene fluoride also has extremely strong flexibility. Flexibility is highly expected during the air scrubbing and cleaning process of membranes, therefore, polyvinylidene fluoride is widely used in membrane filtration forms that require air, such as membrane bioreactors (MBR) and membrane modules in external pressure filtration forms. The results of the actual case investigation indicate that polyvinylidene fluoride film has the lowest wire breakage rate.

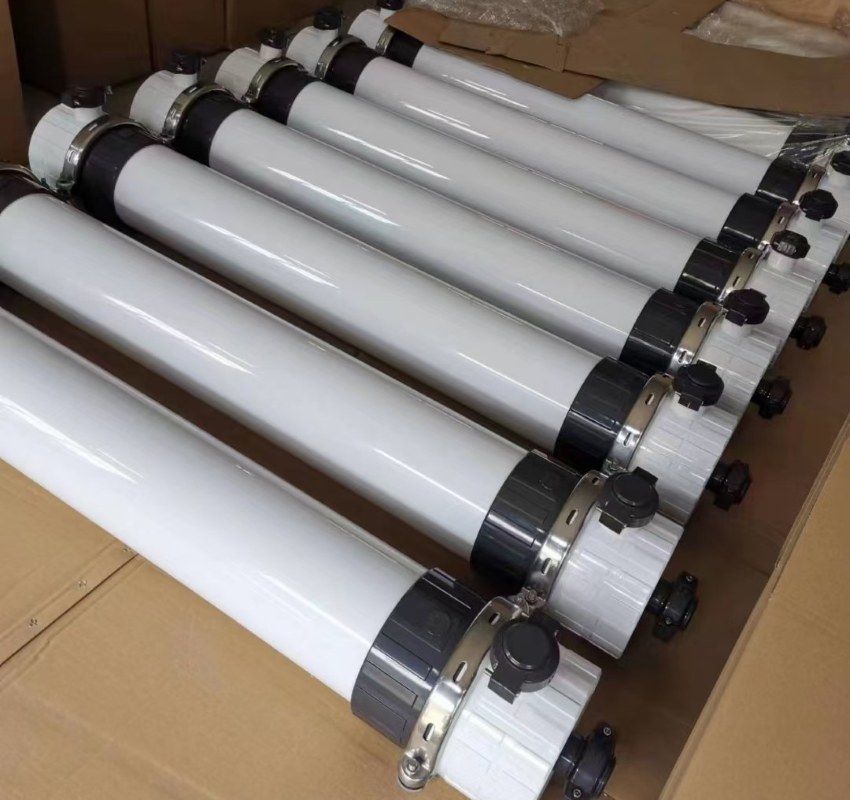

FLISTEC Hollow Ultrafiltration Membrane Technology

Our company's ultrafiltration membrane components include FLISTEC-2860 and FLISTEC-2880 series PVDF ultrafiltration membrane components. Due to their unique antioxidant properties and easy cleaning characteristics, the components can be widely used in groundwater, surface water, sewage treatment, reclaimed water reuse, and tap water purification. Has the following characteristics:

1. High antioxidant and cleaning resistance: The high-quality polyvinylidene fluoride material determines the strong chemical stability of the membrane product, and the high chemical stability of the membrane makes it resistant to high concentration oxidants for cleaning, effectively preventing the proliferation of bacteria and other microorganisms;

2. High flux: The high porosity of the product enables the components to have high flux;

3. High strength and good flexibility: During the cleaning process, air scrubbing can be used to prevent wire breakage;

4. High pollution resistance: Through hydrophilic modification, the product's pollution resistance is greatly improved;

5. Good water quality: The filter membrane has a small nominal pore size, so when using this product, it can remove almost all suspended particles, microorganisms, colloids, bacteria, and bacteria;

6. Long service life: Components usually adopt an external pressure structure that is not easily clogged, with a larger filtration area and higher interception capacity, easy to clean, and more thorough, which can timely remove membrane surface pollution and prolong the service life of the membrane.

Ultrafiltration operation parameter table

Usage conditions:

| Performance parameter | Project | Parameter |

| Membrane element model | FLISTEC-2860/FLISTEC-2880 | |

| Membrane forms | hollow fiber | |

| Membrane material | Polyvinylidene fluoride (PVDF) | |

| Membrane pore size | 0.03μm | |

| Membrane area | 53㎡/75㎡ | |

| Hollow fiber membrane inner/outer diameter | 0.7/1.3mm | |

| Shell Material | Polyvinyl chloride (UPVC) | |

| Fiber bonding material | Epoxy resin | |

| Membrane fiber bundle wrapping net | polypropylene | |

| Filter effects | Suspended solids>2 μm | 100% |

| Microorganism | 99.999% | |

| Turbidity of produced water | ≤0.5NTU | |

| Water Production SDI | ≤2.5 | |

| Product service life | 3-5 years | |

Conditions of Use | Filtering method | outside-in |

| Maximum inlet pressure of the component | ≤0.3MPa | |

| Maximum transmembrane pressure difference | 0.2MPa | |

| Operation temperature | 5-40℃ | |

| PH range during use | 2-11 (pH range during cleaning is 1-12) | |

| Preprocessing accuracy requirements | <150µm | |

| Maximum influent turbidity | 200NTU | |

| Oil content in raw water | <2mg/L | |

| Maximum residual chlorine concentration in the inlet water | 200mg/L | |

| Maximum residual chlorine concentration of cleaning agent | 2000mg/L | |

| Filter flux design | 50L/㎡.h.0.1MPa.25℃ | |

| MODE | cross flow filtration |

Process design conditions:

| Backwash frequency | Every 30 minutes | |

| Backwash time | 60 seconds each time | |

| Backwash pressure | <0.2MPa | |

| Backwash flow rate | 120-150L/㎡.h | |

| Gas scrubbing frequency | 6-12 times per day. The frequency can be adjusted according to the actual situation. | |

| Gas scrubbing pressure | ≤0.1MPa | |

| Gas scrubbing intensity | 7-12Nm3/h | |

| Gas source | Oil free and clean | |

| Backwash water volume during gas water dual washing | 0.5m3/h support | |

| Gas washing time | 30 seconds each time | |

| Washing frequency | Every 30 minutes | |

| Washing time | 30 seconds each time | |

| Positive washing pressure | <0.15MPa | |

| Positive washing flow rate | 3m3/h. Branch | |

| Medication backwash time | Add medication during backwashing and synchronize with the backwashing pump | |

| Dosage | Add medication during backwashing, with a dosage of 10-15ppm (effective chlorine meter) | |

| Medication agents | NaClO | |

Dispersive chemical cleaning | Cleaning frequenc | Wash with acid or alkali once every 24 hours. The cleaning frequency can be adjusted according to the actual situation. Wash with acid or alkali once every 24 hours. The cleaning frequency can be adjusted according to the actual situation. |

| Clean time | 5-10 minutes | |

| Chemical cleaning agents | Acid washing: 0.05% HCl Alkali washing: 0.05% NaOH+0.05% NaClO (effective chlorine) | |

| Chemical cleaning | Cleaning frequency | Once every 2-6 months |

| Clean time | 60-90 minutes | |

| Cleaning agents | Acid washing: 1-2% citric acid or 0.1% HCl Alkali washing: 0.1% NaOH+0.1% NaClO (based on effective chlorine) | |

| Cleaning flow rate | 1m3/h · per component | |

Note: 1. After each chlorine backwash, ultrafiltration water should be used to rinse the ultrafiltration membrane in a straight direction to remove any residual chlorine;

If the raw water is added with medication before ultrafiltration, there is no need to add medication during backwashing; If no chemicals are added to the raw water before ultrafiltration, 10-15 ppm of NaClO (effective chlorine meter) should be added during backwashing.

chemical cleaning

Due to PVDF's excellent anti pollution properties, physical cleaning can generally achieve good cleaning results. But when the physical cleaning effect

When the results are not satisfactory, chemical cleaning should be carried out. Cleaning temperature: The temperature of the standard solution is 20-30 ℃.

1) Chemical Enhanced Backwash: In response to membrane fouling, appropriate chemicals are added from the raw water inlet of the hollow fiber membrane, and various pollutants are removed from the membrane surface and interior through circulation, soaking, and other methods. Maintaining a reasonable cleaning frequency will help to thoroughly remove various pollutants and extend the service life of the membrane.

2) Chemical cleaning: When the transmembrane pressure difference increases by 0.1 MPa compared to the initial value and cannot be restored through methods such as backwashing, gas washing, or chemical dispersion cleaning, chemical cleaning should be performed. Generally, commonly used water treatment agents with excellent bactericidal performance are used for system sterilization treatment, such as sodium hypochlorite, chlorine dioxide, etc; Using acid washing to remove inorganic salt scaling and pollution from membrane systems; Using alkali to wash away organic pollution from the membrane removal system.

Acid washing: Use a 0.1wt% hydrochloric acid solution or a 1-2wt% citric acid solution to clean and cycle for about 60 minutes. If the pollution is severe, the cleaning flow rate can be appropriately increased. This cleaning method is suitable for the removal of inorganic pollutants.

Alkali washing: using a 0.1wt% concentration of sodium hydroxide+0.1% sodium hypochlorite (effective chlorine meter) aqueous solution in the membrane system

Cycle under pressure (<0.05MPa) for 30 minutes, then soak for 30-60 minutes. This cleaning method is suitable for the removal of organic pollutants.

Sodium hypochlorite cleaning: Clean with 500-1000ppm sodium hypochlorite aqueous solution for 60-90 minutes. This cleaning method is suitable for the removal of microbial pollutants.

When performing acid or alkali washing, or using a combination of acidic and alkaline agents, the first step is to replace the membrane with a cleaning solution

The raw water inside the component should be discharged to prevent dilution of the cleaning solution. After completing the cleaning of a certain agent, it is necessary to rinse with ultrafiltration water or RO water and ensure that the pH value inside the membrane module is 7. When the properties of pollutants are uncertain, samples should be used for chemical cleaning testing

If you have any questions or needs, please contact us

Address: No. 1206, No. 66 Yuandong Avenue, Gaocheng Town, Yixing City, China

Phone: +86 18915298518 (Whatsapp)

Email: wxflistec@gmail.com