Are you need Membrane solutions? Free For Business

DTRO disc tube reverse osmosis membrane is a membrane product that can achieve high concentration (high salt, high organic matter, etc.) liquid treatment, recovery, standard discharge, and achieve wastewater concentration and reduction. It is a form of reverse osmosis.

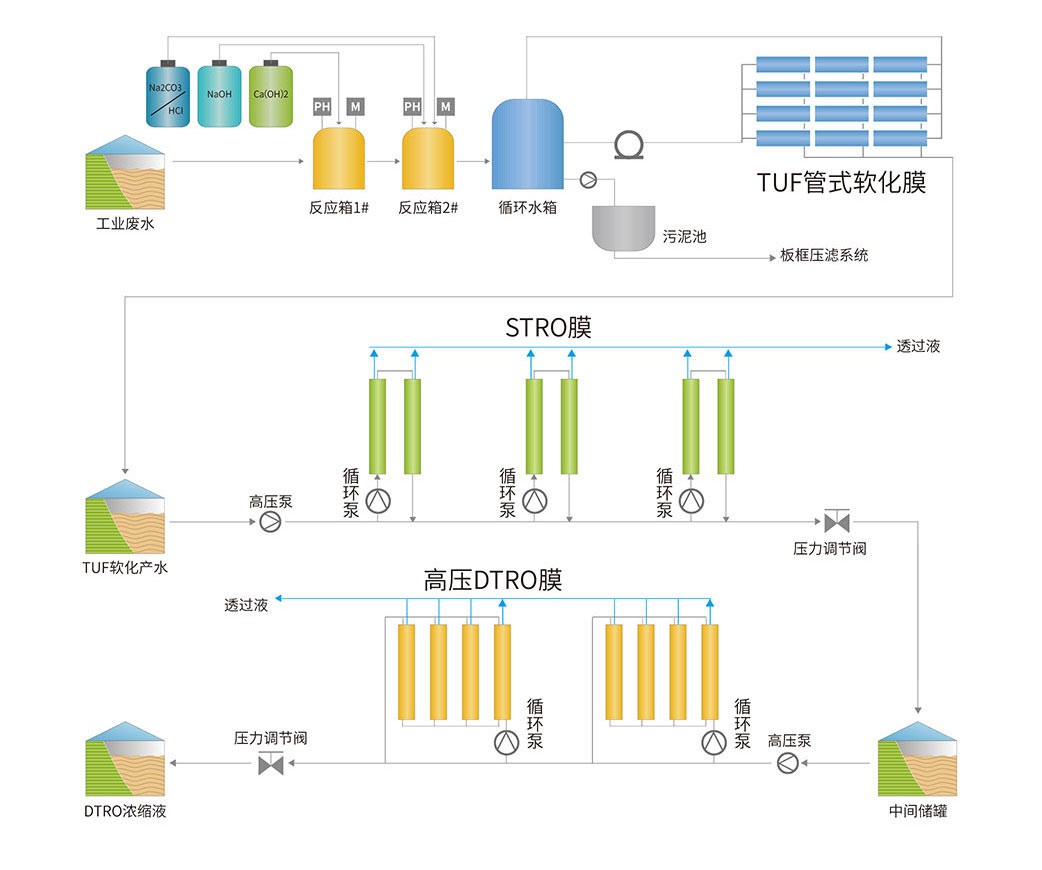

The process stage where DTRO products are located is generally the concentration and reduction stage of high salt and high organic wastewater. Its front-end treatment process may include flocculation, sedimentation (air flotation), sand filtration, ultrafiltration (softening), reverse osmosis, etc., while the back-end treatment process is generally evaporation, etc.

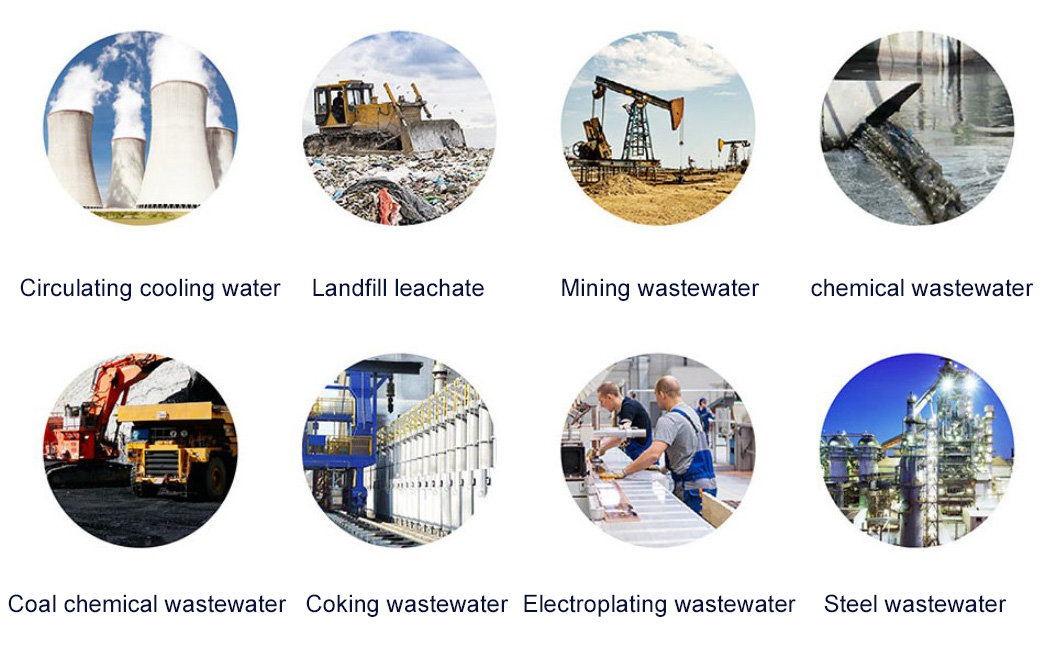

Application scope of DTRO disc tube reverse osmosis membrane

DTRO Disk Tube Reverse Osmosis Membrane - Characteristics

The DTRO disc tube reverse osmosis membrane has the following four characteristics:

Resistant to the "four highs":

High pressure resistance: 75~160bar

High SDI resistance: (SDI pollution index)<15

High COD resistance: 1000~20000mg/L

High TDS resistance: 2000~80000 mg/L

Strong anti pollution:

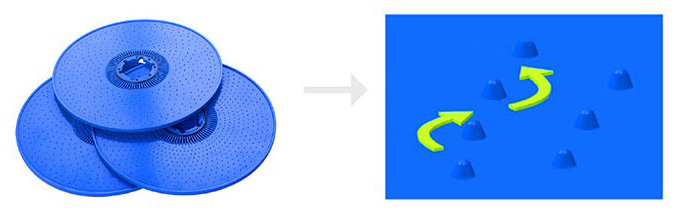

Convex point wide channel:

The guide plate adopts a unique convex point and turbulence optimization design. The open flow channel increases the surface flow velocity (Reynolds coefficient ≥ 5000, 3-5 times that of the rolled film) to avoid solid matter from being trapped on the surface and has self-cleaning function. Effectively reduce concentration polarization.

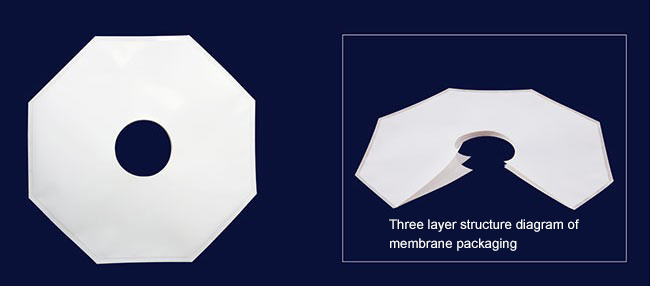

Octagonal structure membrane package:

During high-pressure operation, the patented octagonal structure design causes uneven force points, which will generate high-frequency vibrations under the impact of water flow, driving the water flow to form a 'S' flow towards full turbulence and continuously scouring, avoiding pollution and scaling.

Low cost:

Adopting standardized and modular configuration, easy assembly and disassembly.

Easy cleaning and good performance parameter recovery.

Easy to maintain, can be replaced and reused separately.

Membrane components have a long service life.

Strong adaptability:

High voltage equipment with a recovery rate of over 90%.

Stable water production, with a single processing capacity of 5-100m3/h

DTRO Disk Tube Reverse Osmosis Membrane - Structure

The DTRO membrane column is formed by stacking a reverse osmosis membrane and a guide plate together, fixing them with a central rod and end plate, and then placing them into a pressure resistant membrane shell. Its main components include: pressure bearing nut, water production joint, inlet and outlet joint, upper and lower pressure bearing flanges, upper and lower water passing flanges, membrane shell, center rod, guide plate, membrane package, etc.

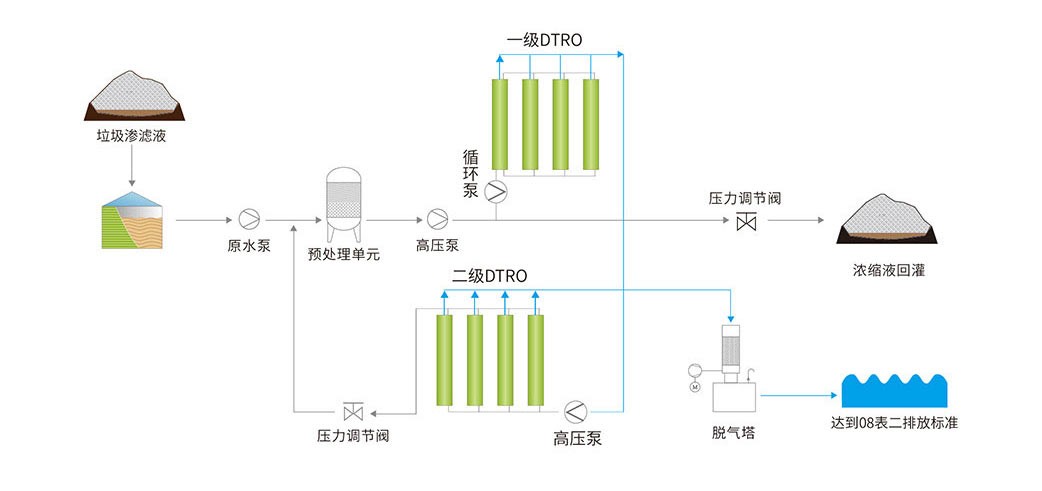

DTRO Disk Tube Reverse Osmosis Membrane - Process Flow

The two-stage DTRO process for leachate is currently the preferred treatment process for most landfills and incineration plants in the industry. It has stable water production quality and can achieve a recovery rate of over 70% for leachate.

DTRO Disk Tube Reverse Osmosis Membrane - Parameter Table

| Model | Unit | DTDOW-9405 | DTDOW-MP9405 | DTDOW-HP9405 |

| Filtering form | / | cross flow filtering | ||

| Water supply flow rate | 1/h | 500-1200 | ||

| Maximum operating temperature | ℃ | 40 | 40 | 40 |

| Maximum cleaning temperature | ℃ | 45 | 45 | 45 |

| Maximum operating pressure | bar | 75 | 90 | 120 |

| Normal operating pressure | bar | 30-70 | 40-80 | 60-110 |

| Normal filtration membrane pressure difference | bar | 5-7 | ||

| Single membrane area | ㎡ | 9.405 | ||

| Membrane module length | mm | 1400 | ||

| Membrane module diameter | mm | 215 | 218 | 224 |

| Operating weight | kg | 74 | 90 | 96 |

| 25 ° C standard desalination rate | % | >98.5 | >98 | >97.5 |

| Inlet and outlet high voltage interface | / | Φ 12mm card sleeve connection | ||

| Water production interface | / | 9mm hose | ||

If you have any questions or needs, please contact us

Address: No. 1206, No. 66 Yuandong Avenue, Gaocheng Town, Yixing City, China

Phone: +86 18915298518 (Whatsapp)

Email: wxflistec@gmail.com